Ideas to Improve Design The first major problem is related to control. The length of line to API sewer is about 17 metersthe slope i used is about 1100.

Liquid Seal An Overview Sciencedirect Topics

I used a basic formula for height calculation P rho g H.

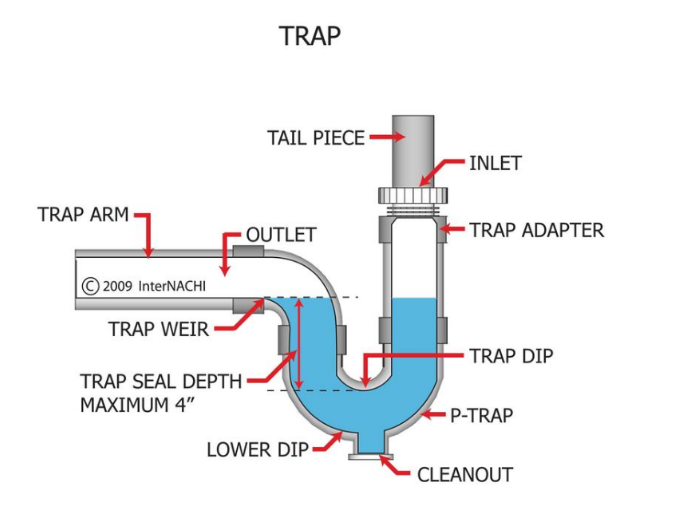

. Reply To This Thread. Generally an 8- to 10-ft loop seal should be adequate. This volume allows the flow of flared gas from inlet pipe to.

If the liquid velocity is more than 1 fts vapour cannot flow against the liquid and the system may siphon and oscillate. Several clones of these models exist. Newest designs developed in the 1980s and 1990s have squeezed out a little more efficiency.

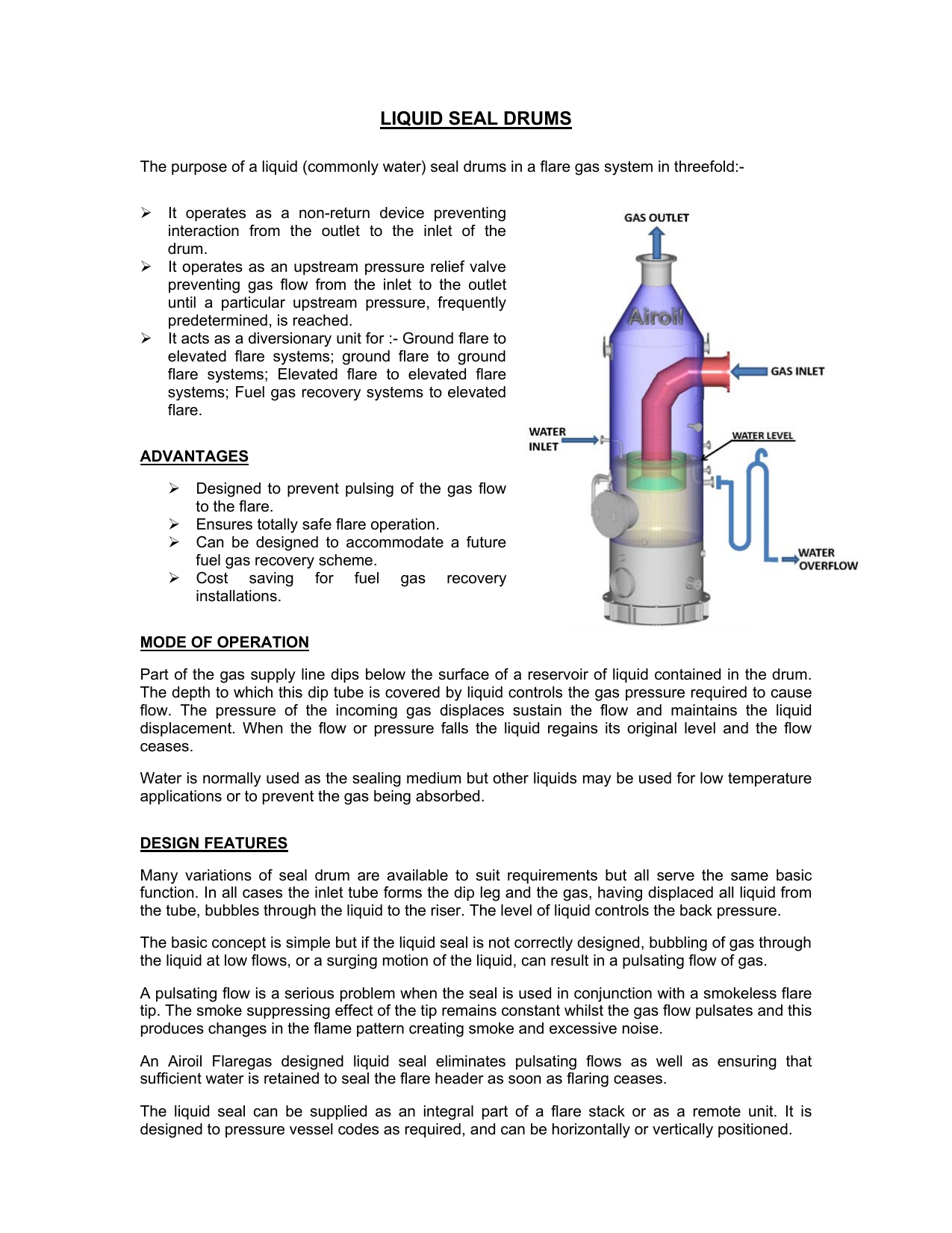

DESIGN FEATURES Many variations of seal drum are available to suit requirements but all serve the same basic function. The flare gas or purge gas is forced to bubble through a layer of water before it reaches the flare stack. The level of liquid controls the back pressure.

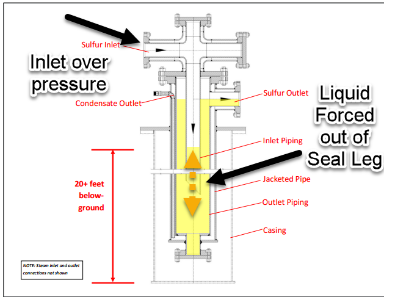

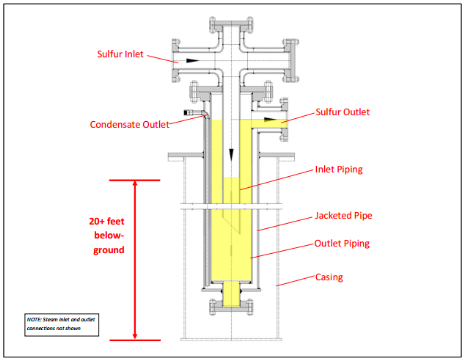

Attached Files condenser hydraulicpdf 1918KB 735 downloads 2 katmar Gold Member ChE Plus Subscriber 651 posts Posted 06 October 2011 - 1027 AM. Figure 3 Sulphur Seal Leg Sulphur flow down centre pipe Returns up annulus Length of seal leg should ensure blower deadhead cannot blow seal Proper heat tracing required on outside of return pipe Figure 4 Figure 4 Lookbox EvolutionLookbox. In refineries some form of liquid seal is typically found in vacuum system seals flare drums sulfur plant rundown legs tank overflows etc.

During normal operation liquid sulfur flows into the seal leg via a rundown. Liquid is held in place by gravity and provides a barrier vapors cant get through. Water or waterglycol mixture is normally the sealing fluid.

333 Fitting and Accessories Design 89 3331 Roof Seal System 90 3332 Roof Seal Material 95 3333 Roof Support Leg 96 3334 Venting System 98 33341 Operation of Bleeder Vent 98 33342 Bleeder Vent Design 101 3335 Roof Drain System 104 33351 Articulated Piping System 105 33352 Flexible Drain Pipe System 107. Our SxSeal 1000 and SxSeal 2000 are two perfect examples of above-ground devices. HminP1-P2102sg - h pipe loss Hmin the minimum seal leg height P1P2 105 pa sg process fluid specific gravity 13 Really appreciate your help and thank you very much.

But this height should be determined by the manufacturer of the ejector or condenser. A seal leg used in a piping system is a vent pipe that functions as a wayto control the fluid Continue Reading. The more is the volume of seal pit the more will be the retention time in this and hence the possibility for slime generation.

The Vapor pressure of hydrocarbon is 1982 psia 125 C and 150 bar. Either way I assume the pipe enter the overhead receiver at the top and there is no submerged internal pipe. Ix 33353 Drain System Selection 109.

Seal water reduction up to 60. Liquid seal drums are vessels that are used to separate the relief gases and the flareheader stack by a layer of liquid. Materials of construction energy utilization packaging system performance and flexibility will be addressed.

The CL series seems like the new design because there are so many of them in operation. This prevents air or gas from flowing backward beyond the water seal. A siphon break is provided.

Quench and Thermosiphon systems heat exchangers buffer pressure systems leakage monitoring and API682-compliant supply systems. I think you will find some useful information on seal legs there. 13-47 h dl f h w h ow Δ 2 where h dl dynamic liquid seal for sieve tray in.

A tapered internal surface abuttingly engages the seal member and provides for centering of the seal member relative to the leg. I want use water or glycol or glycol with water as a liquid-seal. The valve at the bottom of the tailpipe is for draining the unit when it is idle to prevent freezing or rusting and to service the tailpipe equipment.

Carbon floating ring seals Brochure 32 Pages Code. Aper will discuss in detail design considerations involved in selecting steam ejectorliquid ring pump vacuum system for crude tower service. Steam tracing will be use.

Liquid-Seal Drum - posted in Industrial Professionals. L O G O I N T R O D E S I G NMotion Graphics liquidseal adobephotoshop logo graphics graphicdesign graphicdesigner photoshop flyers. Rethinking Barometric Legs by D K Singhal 11.

In all cases the inlet tube forms the dip leg and the gas having displaced all liquid from the tube bubbles through the liquid to the riser. Crude Oil Vacuum Towers require reliable trouble free vacuum systems that operate for months on end between. In one an inverted seal the discharge line is connected near the bottom side of the tank at or below the low-low liquid level and forms an inverted U.

The flowrate i assumed of draining each vessel is 56 USGPM the main header line is of 6. Liquid seals at base of flare stack As indicated in figure-1 liquid seal at the flare stack base is essentially a cylindrical volume of liquid into which the gas inlet to flare stack is dipped. A liquid seal can be maintained by two methods.

If you evaluate on the basis of operational data you will find that the initial suction box handles much more water. From that drum the heavy separated liquid leaves through an underflow line and the light separated liquid through an overflow line. EBES Maintenance-free compact cartridge labyrinth seals with long service life and best performance from EagleBurgmann-Espey.

Skip to content 1 713 731-0030 Toll Free. I like to design the down leg for self venting flow. Emergency-247 Request a Catalog Newsletter.

Katmar Chemical 25 May 10 0100. The basic concept is simple but if the liquid seal is not correctly designed bubbling. Theyre usually in place to prevent flammable or toxic vapors from draining out with liquids.

I would like to ask if there are any other liquids which may be use as a liquid seal in these conditions. Liquid and gas-lubricated mechanical seals eg. Once inside the device sulfur flows downward through the inlet piping to the bottom of the leg and then upward through the annular outlet piping to the sulfur outlet.

Thus either the last vertical down pipe must be very large or you need a vent to break the siphon. I am designing liquid-seal drum which will be working with cold blowdown client say even -100C. The top of inverted U is at an elevation that corresponds to the maximum allowable liquid level in the tank.

The underflow line has a seal leg inverted-U outside the vessel. A leg extends from the main body and has an internal opening therethrough that communicates with the chamber. An electrically non-conductive seal member is received in the leg opening.

Each vessels drain size is 2. A ceramic arc body includes a main body having a chamber. Click Image To Enlarge Figure 1 -- Liquid seal loop system.

The mixed liquids enter a separator drum. 1341 Dynamic Liquid Seal When hydraulic gradient is a factor in tray design the dynamic liquid seal should be used in place of hsl for the determination of effective head.

Liquid Seals On Flare Vent Stack Enggcyclopedia

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

Liquid Seal An Overview Sciencedirect Topics

Sulfur Unit Sulfur Sealing Options Part 1 Brief Overview Of In Ground Sulfur Sealing

0 comments

Post a Comment